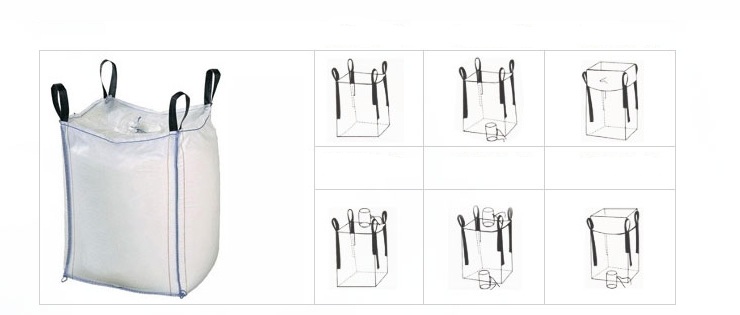

U-Panel Bag:

- U-Panel bulk bags (FIBC) have one (1) continuous piece of fabric for a side, bottom, and opposite side panel creating a “U” shape. The remaining sides and top panel are then sewn in to construct the bag. U-Panel bags are an industry standard and provide a great mix of stack-ability, strength, and affordability.

- Can hold the incredible capacity of weight and possessing the extra lifting capacity.

- Most commonly used design around the world.

- This is one of the cost effective types of design for the packaging of both dry (bulk) and liquid (bulk) shipments.

Circular Or Tubular FIBC:

- Circular bulk bags (FIBC) have a circular/tubular body that is a seamless. With only a top and bottom panel sewn into the bag, circular style bags are ideal for fine and hydroscopic materials.

- There are no stitches on the sides making it more favorable for the sift proof & leakage free bags.

Q-Bag OR Baffle Bags / Panel Bag:

- This Bulk Bag /FIBC bag is made panels with baffles inside, which distribute the weight of the product evenly within the bag. Baffle helps stabilize the bag, reduce product shifting during transportation & prevents it from bulging.

- Prevent the sides of the Bulk bag from bulging.

- Bag remains a square instead of having a circular foot print.

- Cost effective in transportation and storage.

- Less Packaging, Transport, Storage, Handling & Administration.

- Improved stability of the packaging, enabling more safety stacking.

Lifting Loops, Filling and Closure and Discharge:

Lifting Loops:

Filling and Closure:

Discharge: