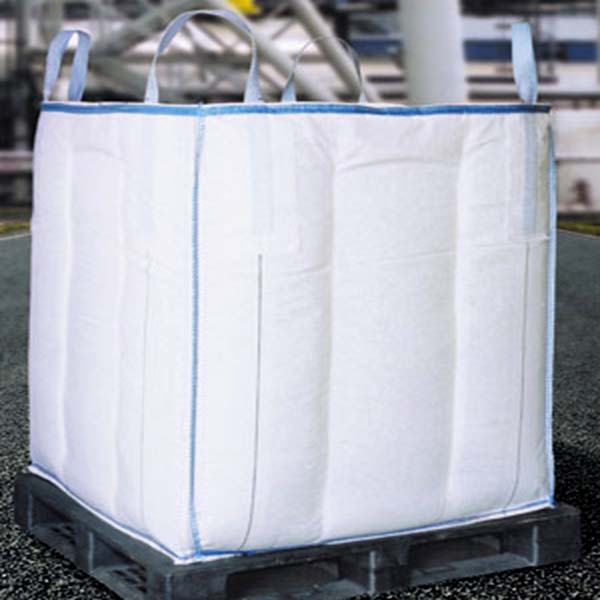

Flexible Intermediate Bulk Containers (FIBCs) or Bulk Bags as it is popularly known today are giant size bags in drum or box shape. These bags are made of high tenacity Polypropylene (PP) material and are UV stabilized with certain additives to give more shine to the bag and TiO2. They are produced in a range of capacities from 250KG Safe Working Load to 2500KG Safe Working Load with a Safety Factor 5:1 (Single trip) and 6:1 (Multi trip), depending on the density of the bulk material that is handled in the bag. These bags are normally tailor made to meet the specific requirements of the end users.

At Omniscient, we provide a wide range of these Bulk bags to meet today's diverse packaging requirements. We offer them with different sizes, strengths, fabric weight, loop designs, top and base designs, inner liner or lamination (outside/inside the bag) and various printing options. We can do a maximum up to six color printing on our Bulk bags as per the customer’s requirement. Our FIBCs are made in different colors and we can use multi-colour webbing to give them a different and a unique look all together.

- Ideal, cost effective, economical and highly feasible source for packaging of free flowing material in the granular, power or crumble form.

- Very easy to store and handle the FIBC with a standard equipment.

- Bulk bags when not in use could be easily folded and requires very less space in comparison to the storage of empty fibber drums and other containers used for packaging.

- Bulk bags/FIBCs once packed and filled with material does not require any additional packaging.

- FIBCs are packed flat and square in a bale for the delivery of FIBC bags to the end users for the its consumption.

- Depending upon the bulk capacity of the product and its application, the FIBCs/Bulk bag comes with the guarantee of the Safe Factor of 5:1 and 6:1 for the Dangerous goods.

- Industrial grade clean production.

- Safe Working Load ( SWL) : 500 KG to 2500 KG.

- Safety Factory ( SF) : 5:1 ( Single trip), 6:1 ( Multi Trip) or as per customers requirement.

- Size, Color & Type of FIBCs: As per the customer requirement & purely customized.

- Printing : Up to 6 Color Printing on each sides.

- Loops, Filling & Discharge options : As per customers requirement.

- Liner : PE Liner from 40 to 120 Micron Thickness.

- Packing: Packed on either Bale or Pallets.

- U-Panel Bag - Requires 2 seams along 2 opposing sides to create 2 panels and a U shaped bag.

- Tubular - Circular fabric with with seams sewn at the top and bottom of the bag.

- Baffle- Utilizes inside baffles that allow the bag to fill to maximum capacity without expanding.

- Color Options - As per customers Requirement (Minimum order quantities required).

- Uncoated - Standard polypropylene fabric.

- Coated - Fabric that is laminated with polypropylene film.

- Conductive - Fabric which conducts electrostatic charges.

- Open tops - Economical for in plant use, but not optimal for packaging.

- Duffle tops - Top opens out of the bag for easy filling.

- Inlet spouts - Top wraps around your filling spout for the best combination of easy filling and spill free shipping.

- Cone top - Allows optimal filling space for products that need time to settle.

- Flat Bottom - Basic polypropylene fabric bottom with no discharge capability.

- Discharge Spout - Allows bag to discharge from bottom in a smaller capacity.

- Full Bottom Discharge - Allows entire contents to be discharged in one motion.

- Closures - Tie closure, velcro closure, diaper closure, star closure, drawstring closure.

- Side seam - 4 loops sewn directly into the side seam.

- Cross corner - 4 loops sewn across the corner for easy forklift access.

- Stevedore straps - 4 loops sewn directly into the side seam with 2 straps connecting the side loops.

- 1-loop - 1 large loop connecting two opposite sides for easy crane access.

- Sleeves - 2 sleeves sewn on opposite sides of the top for easy forklift access.